Material-efficient Cu wire-based 3D printing technology

Area Acceleration (D2) Segment Upscaling (D2.2) Duration 2019/01/01-2021/12/31

Material-efficient Cu wire-based 3D printing technology

Area Acceleration (D2) Segment Upscaling (D2.2) Duration 2019/01/01-2021/12/31

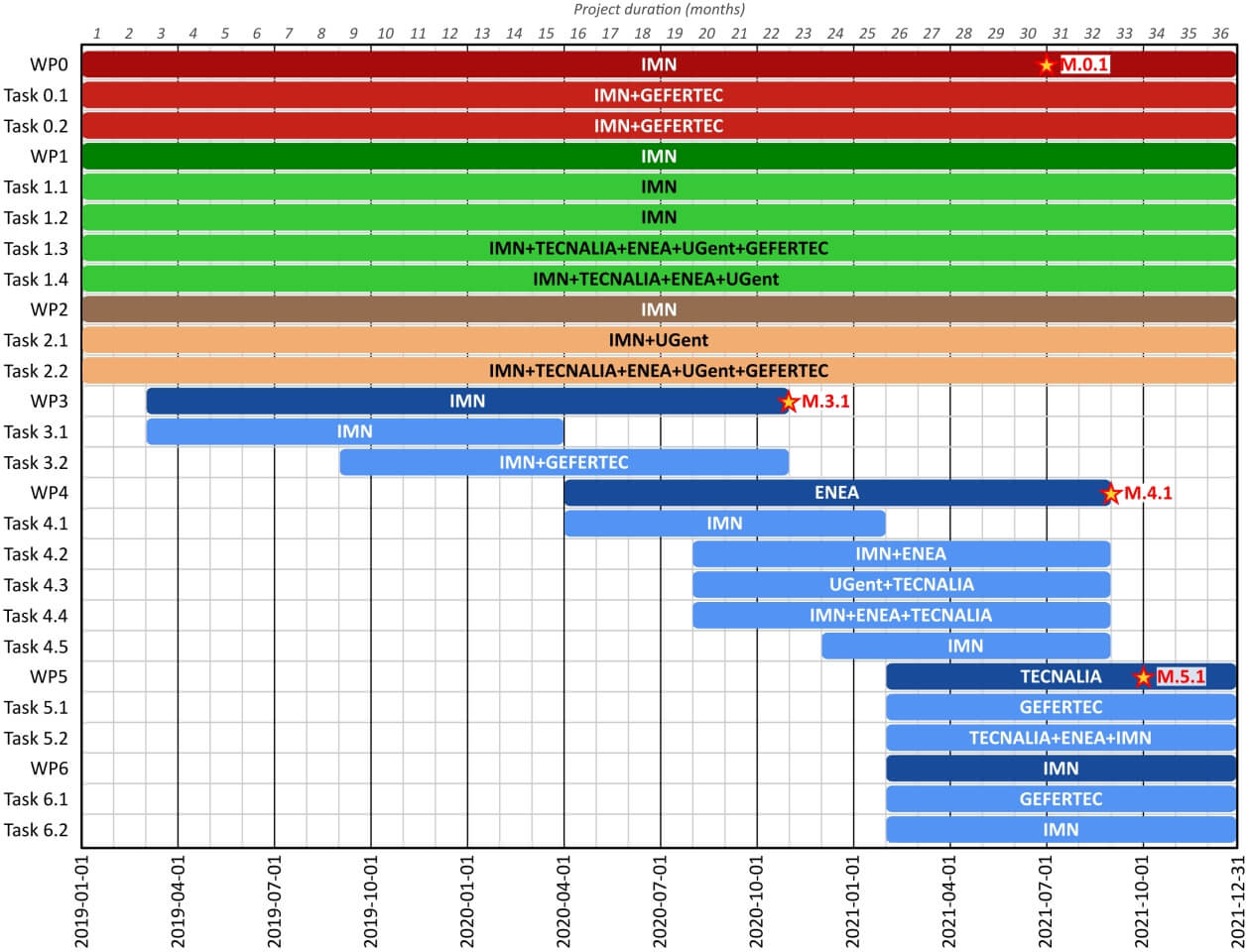

The project implementation schedule is divided into 6 Work Packages (Gantt chart, Fig. 1), and during the first year, four of them (WP0 – WP3) will accur.

WP0 – include the market analysis, with main emphasis on the target end users in the marine sector and the technical, operational and financial feasibility studies.

WP1 – is focused on management, monitoring and control activities and will last for the entire duration of the project.

WP2 – is aimed at educational aspects connected with the project theme and professional development. It will start from the beginning of the project and lasts for the whole project duration.

WP3 – will start in the third month of the project and will be focused on the selection and optimization of the chemical composition of the copper alloys from the Cu-Al system. The input wire materials for the AM process will be produced and subjected to detailed material analysis.

Fig. 1. Gantt chart.